NEWSLETTER

Wpisz swój adres e-mail i zyskaj e-booka

Bez niechcianej poczty ani reklam

Tylko merytoryczne treści z obszaru digitalizacji produkcji

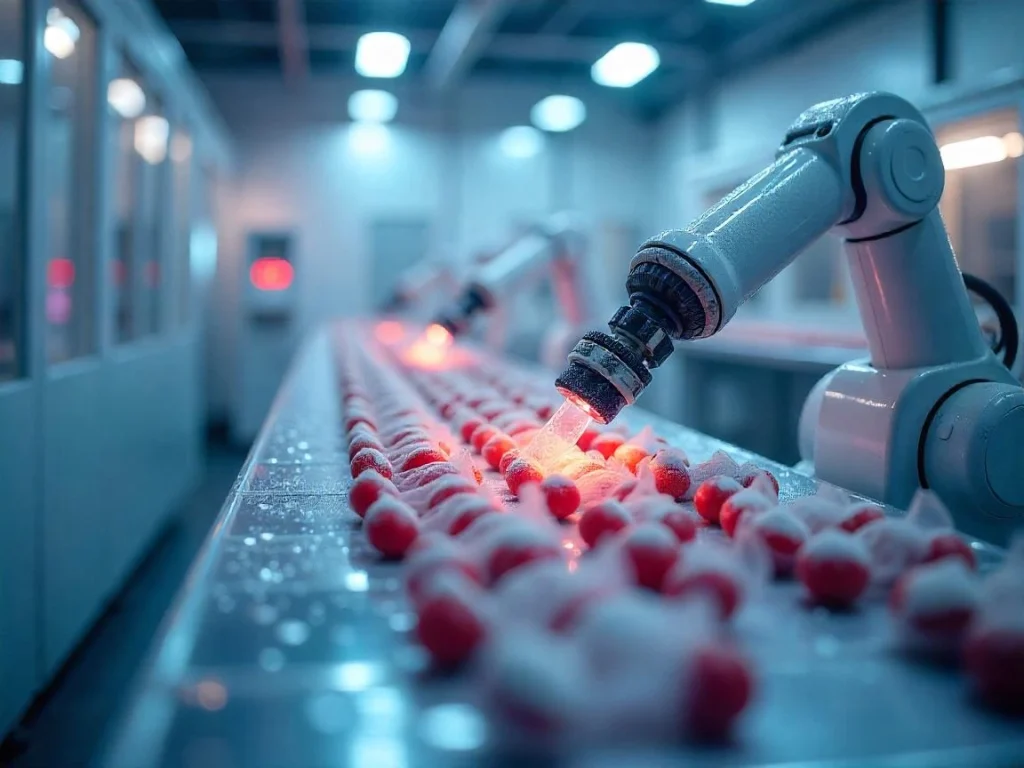

Automation and robotization – modern manufacturing processes and the introduction of digital transformation assumptions are inextricably linked to these two terms. Although these terms are often used interchangeably, they denote completely different approaches to optimization.

Process automation focuses on eliminating repetitive, manual activities by implementing digital solutions and control systems. Robotization, on the other hand, refers to the use of physical machines that are capable of working independently. Selecting the right technology for a factory’s current needs depends on the specifics of the process, current infrastructure, implementation costs and expected results.

But what are the differences between automation and robotization? When is it worth choosing to implement one of these solutions? Find the answers to these questions in this article.

Automation makes it possible to reduce or eliminate manual work by implementing appropriate technologies. It can apply to both simple administrative activities and complex industrial operations. Its introduction allows selected processes to occur faster and be optimized. It also reduces the impact of errors due to the human factor and saves time and resources.

Automation of production processes allows to increase productivity and streamline daily work. However, this concept does not always mean the implementation of robots. In many cases, the introduction of appropriate software or control mechanisms turns out to be sufficient.

Robotization is a specific type of automation, not an interchangeable term for it. It involves the deployment of robots that perform specific physical tasks in a repetitive and precise manner. In this case, industrial robots often replace humans (or in the case of cobots – cooperate with them), especially in processes that require high accuracy, high strength or work in difficult conditions.

An important point is that robots do not operate in isolation. They are usually part of a larger technological process. They can cooperate with other machines and control systems. Robotization of production allows to standardize processes and increase their efficiency. However, the implementation of such solutions often requires more money than classic automation.

Get 5 chapters of the book for free!

Join the newsletter and gain access to 40% of the book

“15 Steps to Buying an Information System“.

The decision to implement automation or robotization of production processes should be preceded by a detailed cost-benefit analysis. In this case, it is worth taking into account:

Deciding to invest in production automation or robotization should take into account the specific goals and benefits we want to achieve through its implementation. Some of the most commonly cited reasons for such implementations include:

While the introduction of robotization and automation of manufacturing processes can bring a number of benefits, it is not always the best solution. One common mistake is to implement them without an implementation strategy, thorough needs analysis and ROI estimation. Some processes may also require frequent modifications, making their robotization too costly and unprofitable. Lack of integration with already existing infrastructure can also be a significant problem. When implementing innovative technologies, it is worth making sure that they will work with ERP, MES or SCADA systems already in use.

Automation and robotization are tools for streamlining processes in companies, but each has different applications. Robotization will work well where precision and repeatability are needed, while automation can apply to both production and administrative processes. It is important to make the decision on implementation based on an analysis of the company’s needs and the costs and benefits associated with the planned investment.

Automation and robotization – if you’re interested in this topic, I discuss it more extensively in the latest episode of the Digitalizuj.pl podcast ! There I explain in detail how these solutions differ, give specific examples from the industry and show how these technologies can improve production processes. See which solution will work best for your factory and how to implement it effectively!